Building on the success of my Subaru BRZ TL70 6 speed conversion for the Datsuns I decided to see if it was feasible tho do the same for the Triumph TR6. There are 5 speed conversions available but no 6 speed. Having had TL70 in my 240Z for a few years now I can say with some certainty that having the 6 speed greatly improves around town driving. The TL70 is a single overdrive which means that from first gear to 1:1 is broken up in 5 segments rather than 4 on 4 speeds and 5 speeds. This really improves the drivability since it’s a lot easier to keep the RPMs in the cars happy place.

Pros and cons of the TL70 conversion.

Pros: My criteria for deciding on whether or not to pursue a conversion is pretty basic. Are the transmissions available new and can the conversion be done in someones driveway

The answer on that is yes. If you want to source parts on your own and do the conversion yourself we offer all of the items individually. The TL70 is available new for around $2500.00 USD plus shipping but you can source used ones for much cheaper. There is obviously risk buying a used transmission so the majority of people just take the path of least resistance and get a new kit. Both the prototype 280Z and my personal 240Z are running used transmissions with zero issues. Buying from a legit wrecker with milage documentation is your safest bet.

I partner with Godzilla Raceworks who handles new transmission conversions as well as the assorted parts needed for the conversion. They will be working with me on this bell housing as well. They ship worldwide.

Cons: Really the biggest one is no provision for a speedo cable. While not a deal breaker since there are solutions it will still involve additional expense if you don’t have a GPS speedometer already. The most straight forward way is a Speedhut Speed Box. It’s a device that takes GPS data and spins your speedo cable. The second is to replace the speedo with a GPS speedometer.

It uses a tradition external slave cylinder. I’m setting it up to use a Datsun slave since I know that will work but my goal is to design a bracket to make the factory slave work. The stock TR bracket may work but I won’t know that until I do the first test fit.

Spec Clutch will provide a TR6 clutch that uses their TR6 plate and their TR6 disk with a BRZ hub installed.

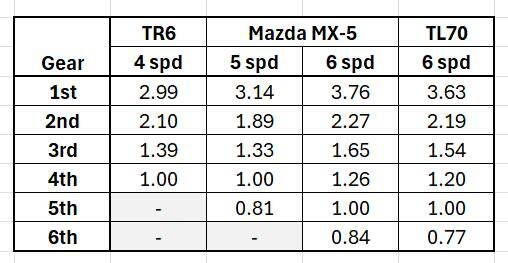

Steve G from The Triumph Experience was kind enough to put this ratio chart together.

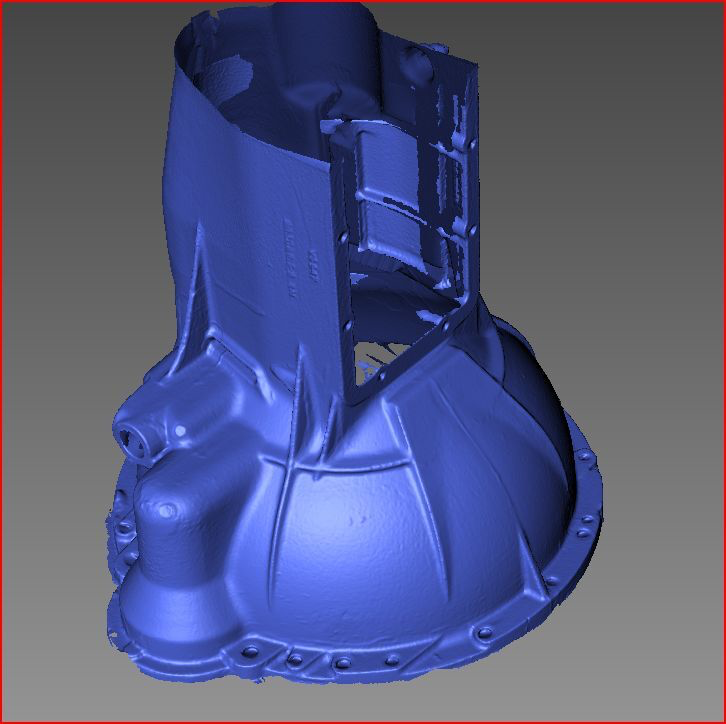

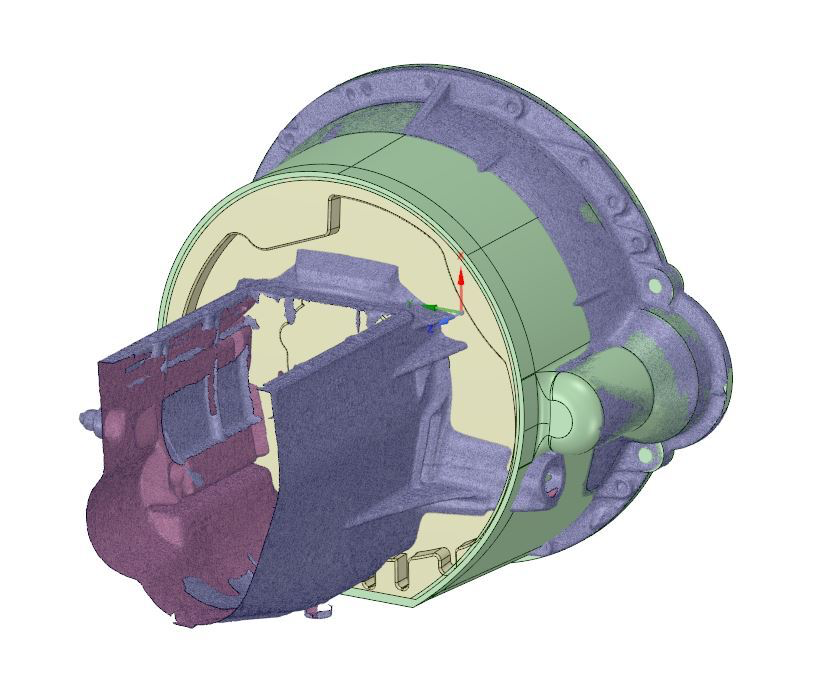

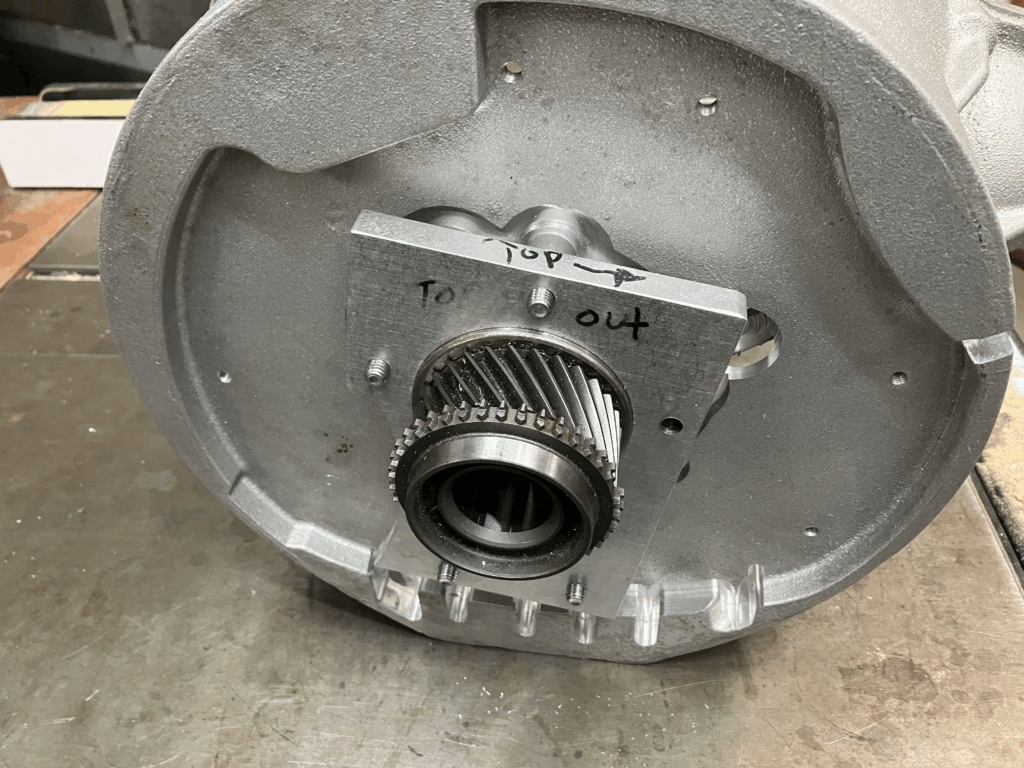

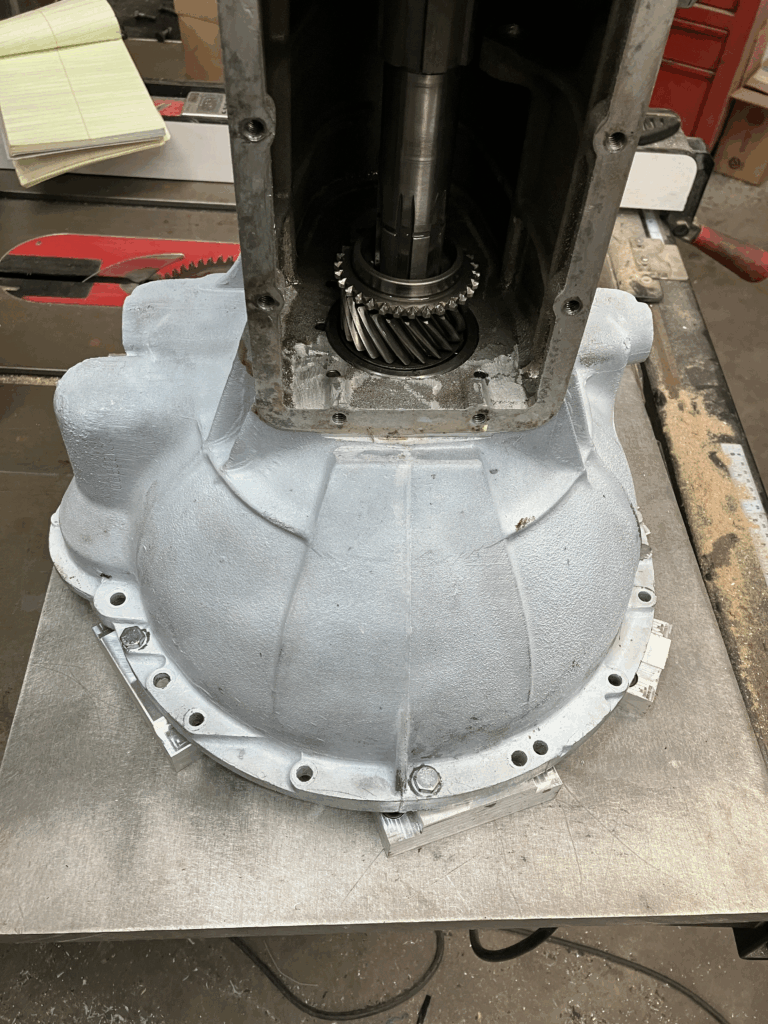

I bought a used TR6 gearbox and gutted it. I then scanned it with my white light scanner.

I then started the solid modeling process using my existing TL70 parts and using the mesh as a guide to make sure I pickup the necessary features.

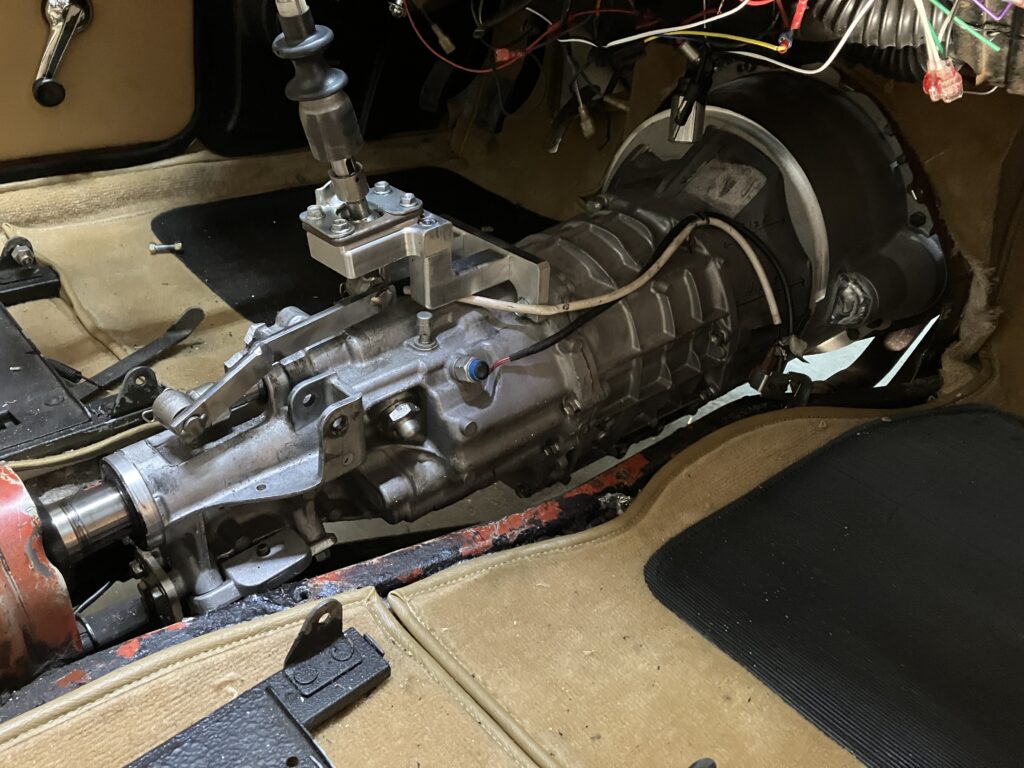

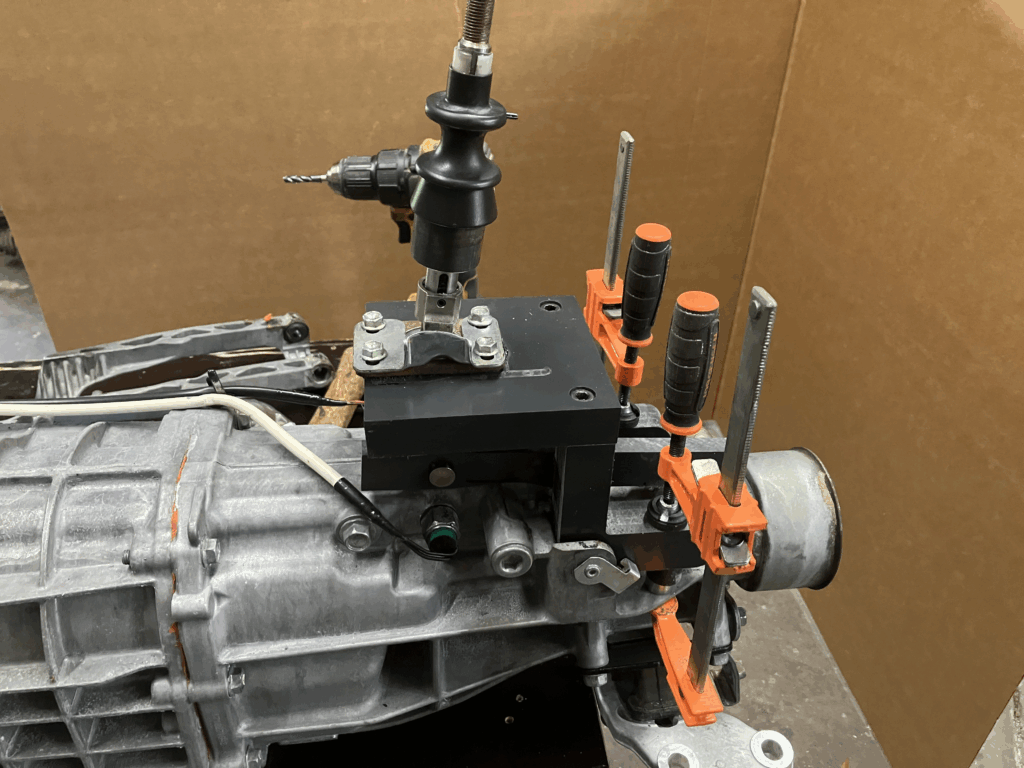

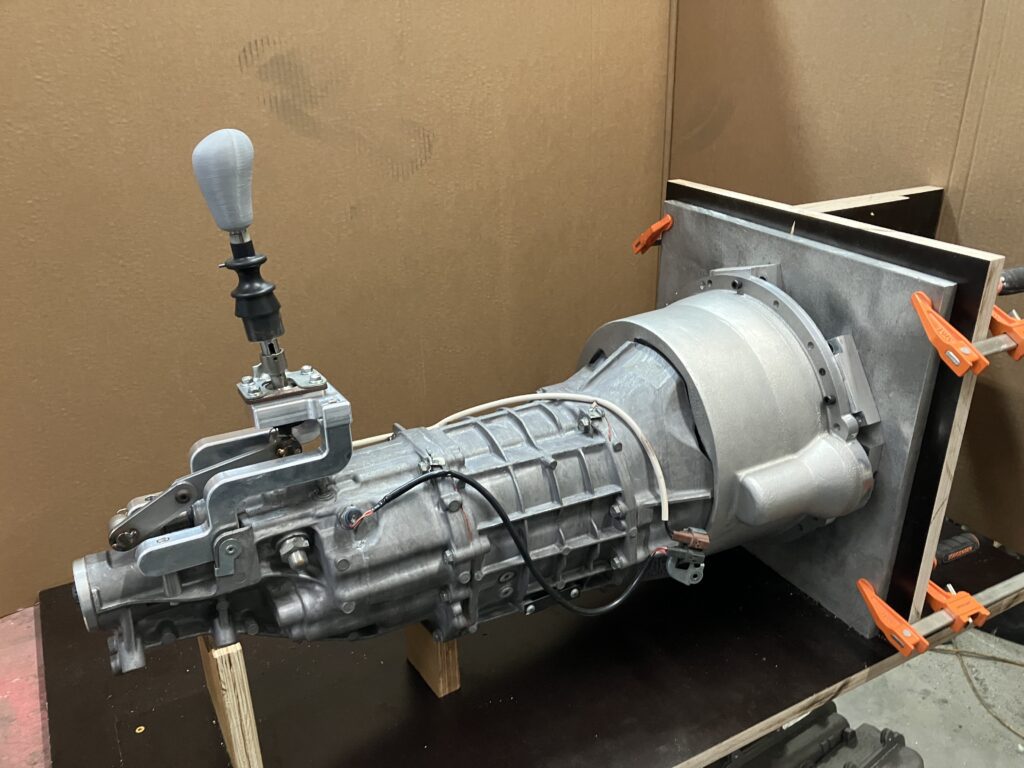

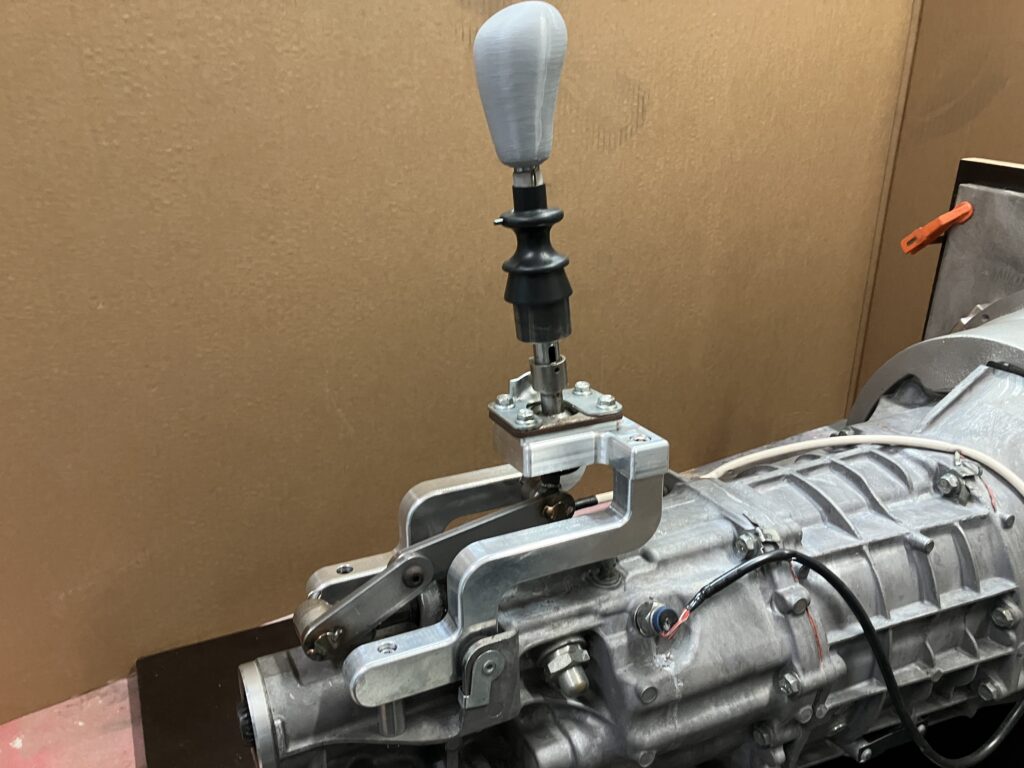

I bought a used TL70 so I could mock up the shifter. In order for this to work the shifter has to be in front of selector rod and that was causing a lot of geometry uncertainty. Generally the way I work is to prototype with plastic and then get as much data as I can and adjust. Rinse and repeat. Since I already had a ton of data from designing the Datsun shifter I was able to get good results on the first try. It shifts and with a better link bar it will be fine. The position of the shifter fore and aft lines up with the existing opening.

Based on the success of the shifter I decided to go ahead and make the foundry pattern.

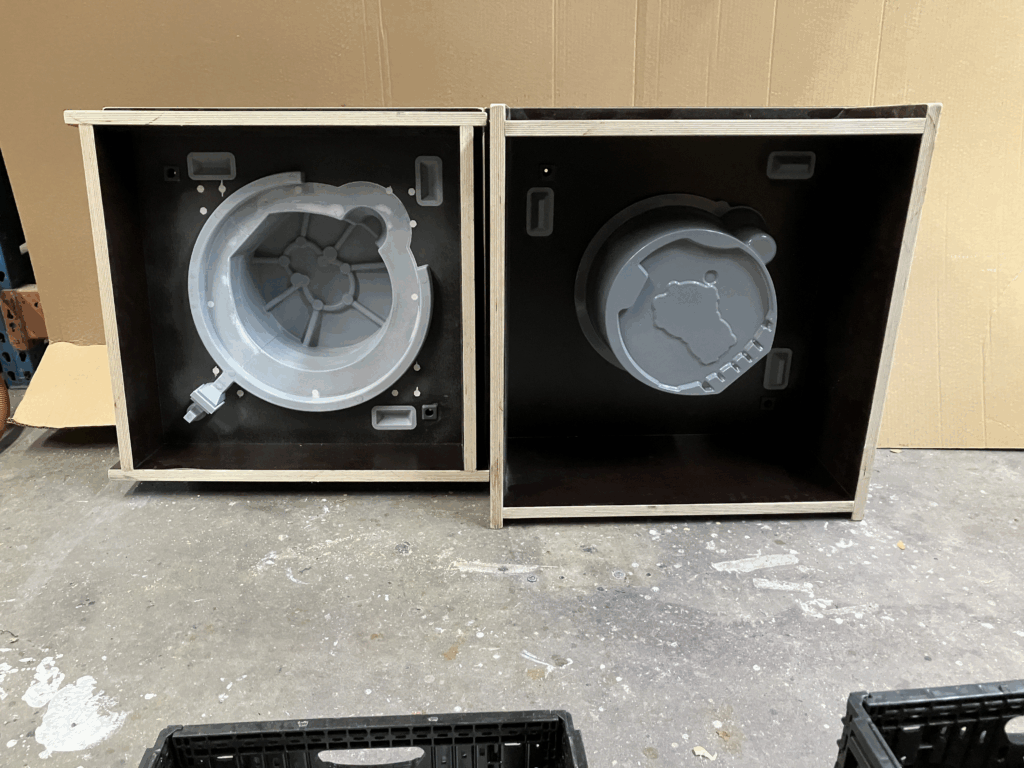

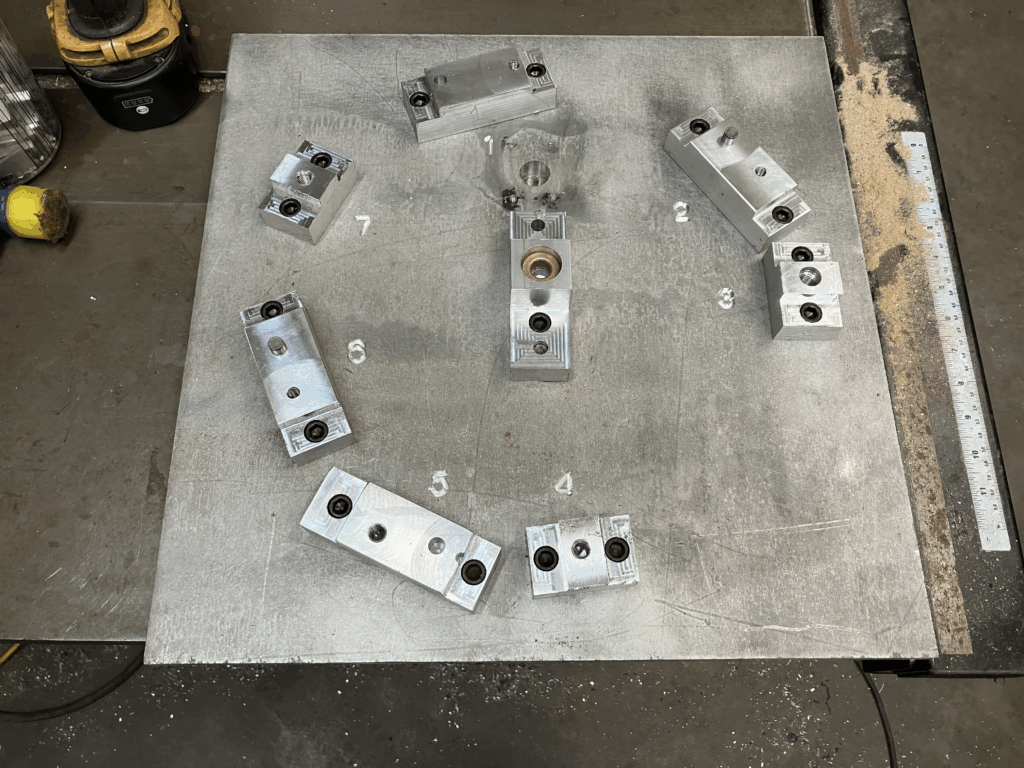

While waiting on bell housing castings I figured I’d work on a new test rig that I’ve been planning on doing. We test each and every bell housing two times for alignment. The test method is we install a master front cover in the bell housing along with an input shaft and bearing.

We then bolt this up to a test block and crank with the appropriate pilot bushing installed. We spin the input shaft and make sure there is little to no drag. The first test happens during the machining process. The second test is identical except it’s done with it’s forever cover installed and right before it gets boxed up.

Since I don’t have a Triumph block and crank I figured this would be a good time to build the rig. As it sits I can test Datsun and Triumph bell housings. Positions 3,4,5, and 7 are for the Datsun and 1,2, and 6 are Triumph. I have .375” dowels in all three blocks since that is what I measured when I reverse engineered it. Based on what I have read the dowels on 6 and 2 are the only ones it uses. The center block holds the pilot bushing. I have it set up with a Triumph bushing in it’s correct position based on the wear pattern I picked up from the old transmission.

The Triumph transmission dropped right on the dowels and after tightening the hold down bolts the input shaft spins freely and the bushing is correctly positioned.

Now that I have this data I can easily design the pilot bushing adapter based on the known location of the Triumph bushing.

Picked up the first 2 castings today and they look pretty good.

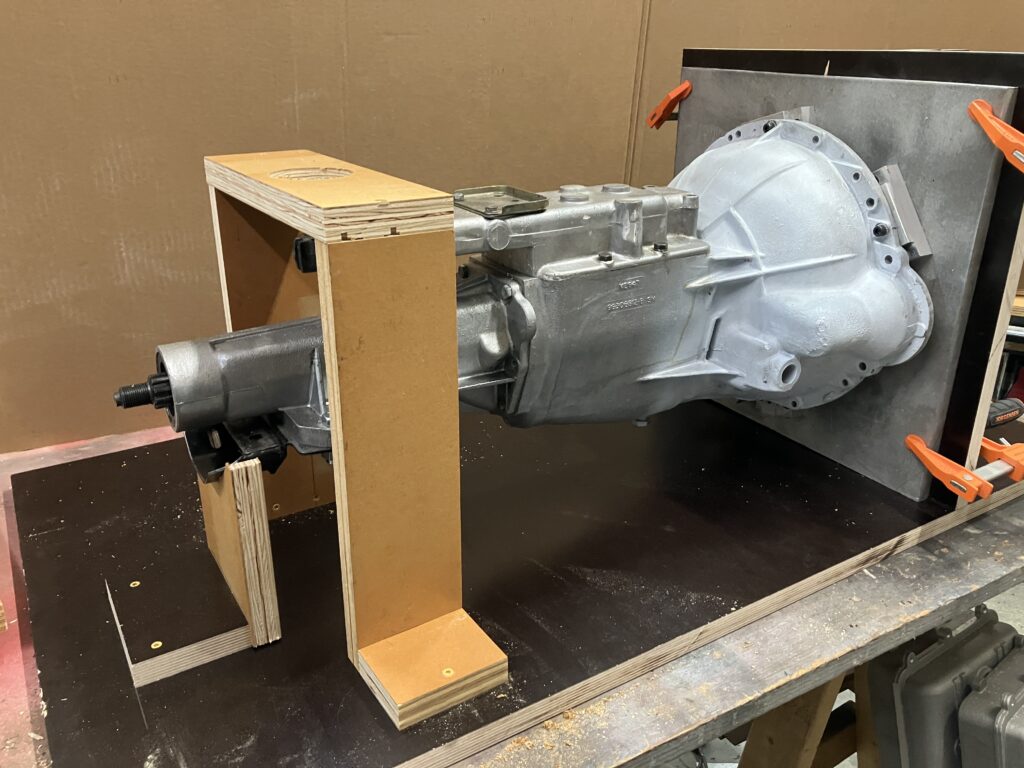

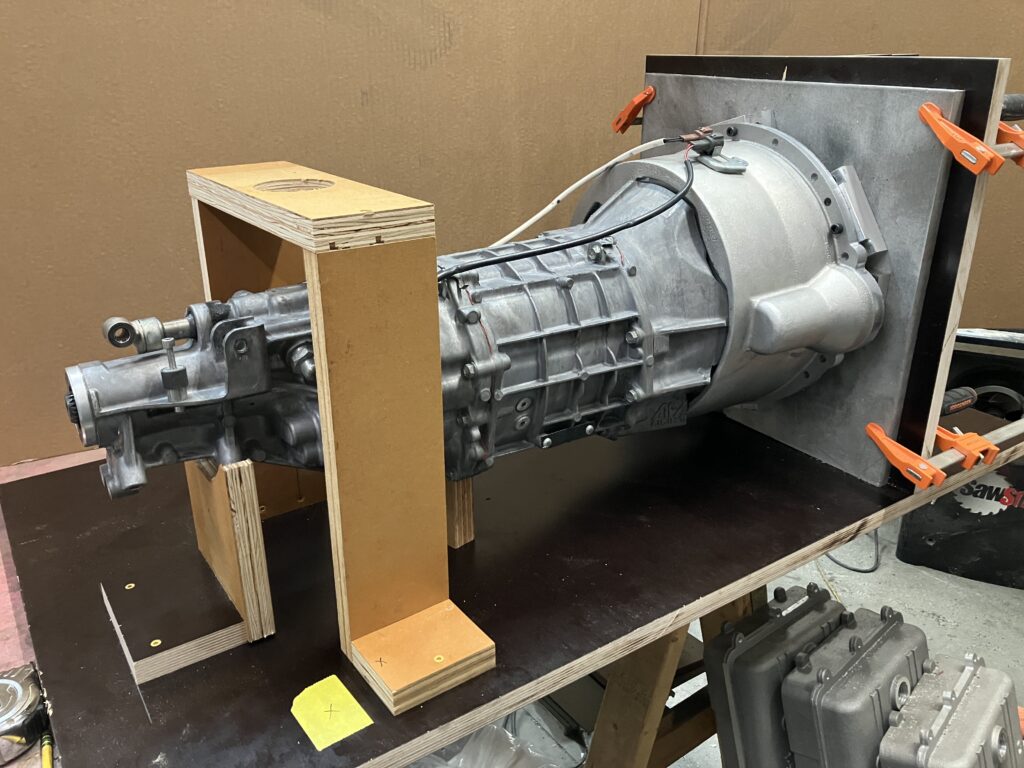

I built a mock up rig in order to get the shifter and cross member in the right place.

Here is The TL70 with the prototype bell housing.

It looks like the cross member on 73-76 cars may work using the existing bosses on the TL70.

Finished up the shifter. Works great.

Video of running through the gears

At this point I’m kind of stalled since I don’t have a car to finish the driveshaft length and to finalize the transmission mount.

Did some work on the prototype bell housing today. I did the machine work on the clutch release arm.

I added the provision to use a Datsun slave in case I can’t get the factory TR6 unit to work. If the TR unit works then I will probably do away with this. It’s basically a failsafe at this point since this setup has been proven already.

Just received the TR6/TL70 clutch kit from Spec clutch. Fits the TL70 input and has a diameter of 8.5″. Still hope to have the test car here next week so I can finalize the rest of the parts.

Well it fits!

The output shaft may be a little high but I won’t know until I get the drive shaft. The engine tilt is within .01 degrees of where it was with the stock transmission and less than wonderful rubber transmission mounts. The shifter is centered on the tunnel hole but may be a little high. Minor stuff really.

TR6/TL70 6 speed. First test with the pilot bushing adapter. Pretty stoked. Also checked clutch disk spline engagement and I have splines on both sides of the hub and that’s good enough for me

The only issue is unbeknownst to me the engine in the 74 I borrowed is a 1969 so the pilot bushing is a different arrangement. Just another curve in the road.

Shot without the flywheel. The adapter is steel with an off the shelf bushing pressed in.

Hit another engineering milestone in the project. Clutch release.

Stock TR6 components. .75″ master cylinder. A little firmer than my 240Z but it’s super close. Hard to tell because there is no seat in the car and I’m sitting on a folded up moving pad. There may be enough travel in the system to run a .70 master but for now I’m happy. Still lots to do but I have good forward momentum.

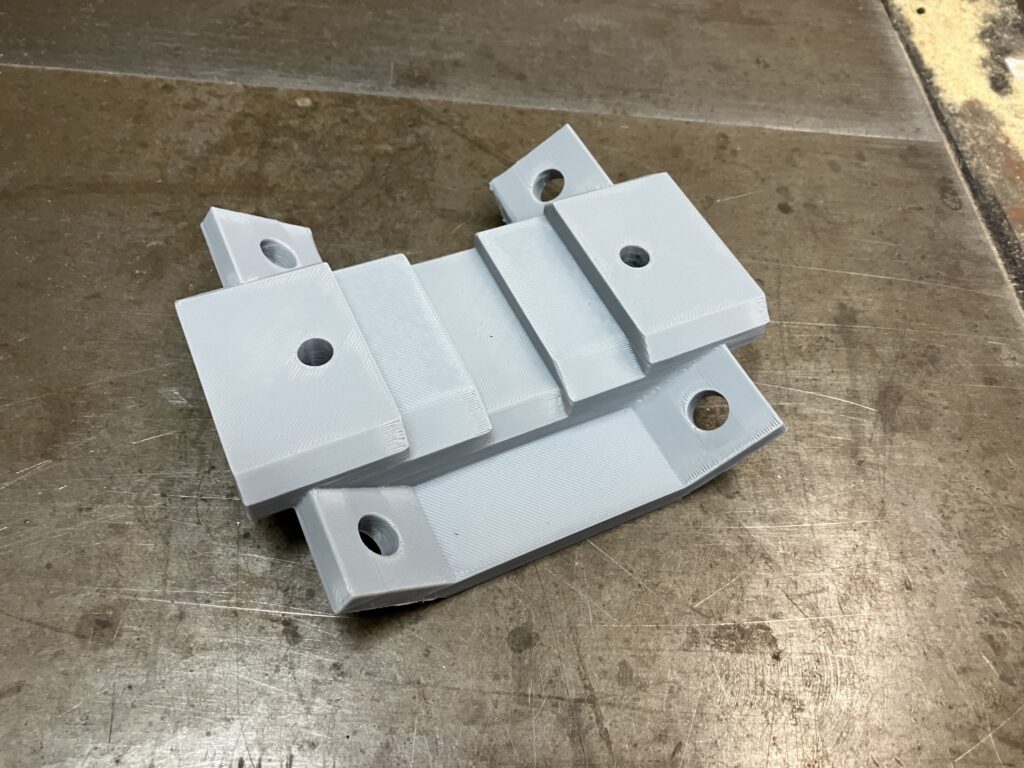

Time for some updates. I installed the transmission and realized pretty quickly that I was going to need something custom to get from the V shaped TL70 tail housing to a flat plane. After a few 3D printed mockups this is what I ended up with:

I then made a foundry pattern to cast them. I’ll be receiving the first articles today so hopefully I’ll be able to finish off the crossmember.

The shifter in my original configuration just wasn’t going to clear the tunnel so I had to do a pretty major redesign. I designed a bracket that amounts to the top two case bolts and the arms bolt to that. Actually worked out well.

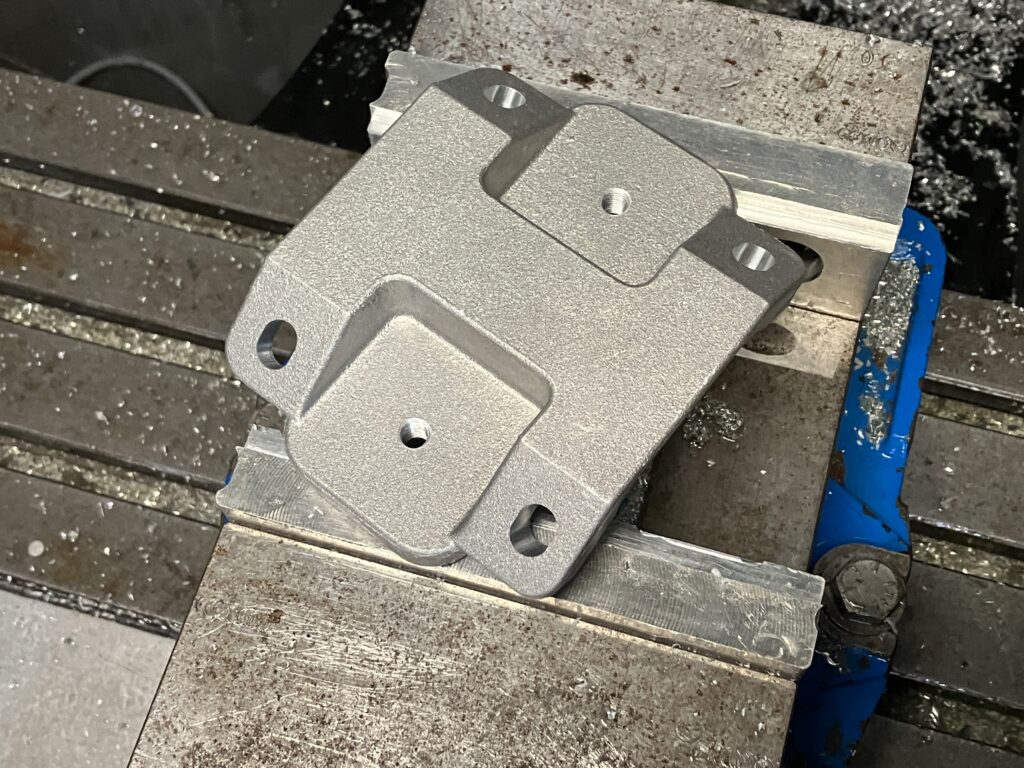

Got the castings from the foundry. I was in a hurry so they didn’t grind the part line.

After machining:

Fits great:

Last piece of the puzzle completed.

I have a fiberglass tunnel and a two piece poly tunnel and they both fit like crap But the shifter sits nicely in the console and I’m figuring on some minor tweaks. The hole in the fiberglass tunnel is about 1/2″ forward of the 2 piece poly tunnel. Not only that there was no way the lower shift boot would fit in the hole. I have all the data I need to move to the next phase which is actually putting a 6 speed in a running TR6. I’m pretty sure I’m picking one up at the end of the month.

So a lots been happening….. Just not updating this page. I purchased a 1973 TR6 and used it for the conversion. At this point I have everything worked out . I posted a first drive video on YouTube and I’m super happy with the way it drives. Everything is working as it should. I ended up making the stock Subaru boot work with a custom 3D printed retaining ring.

You’d never know there’s a 6 speed hidden in there.

Here is the first drive video: