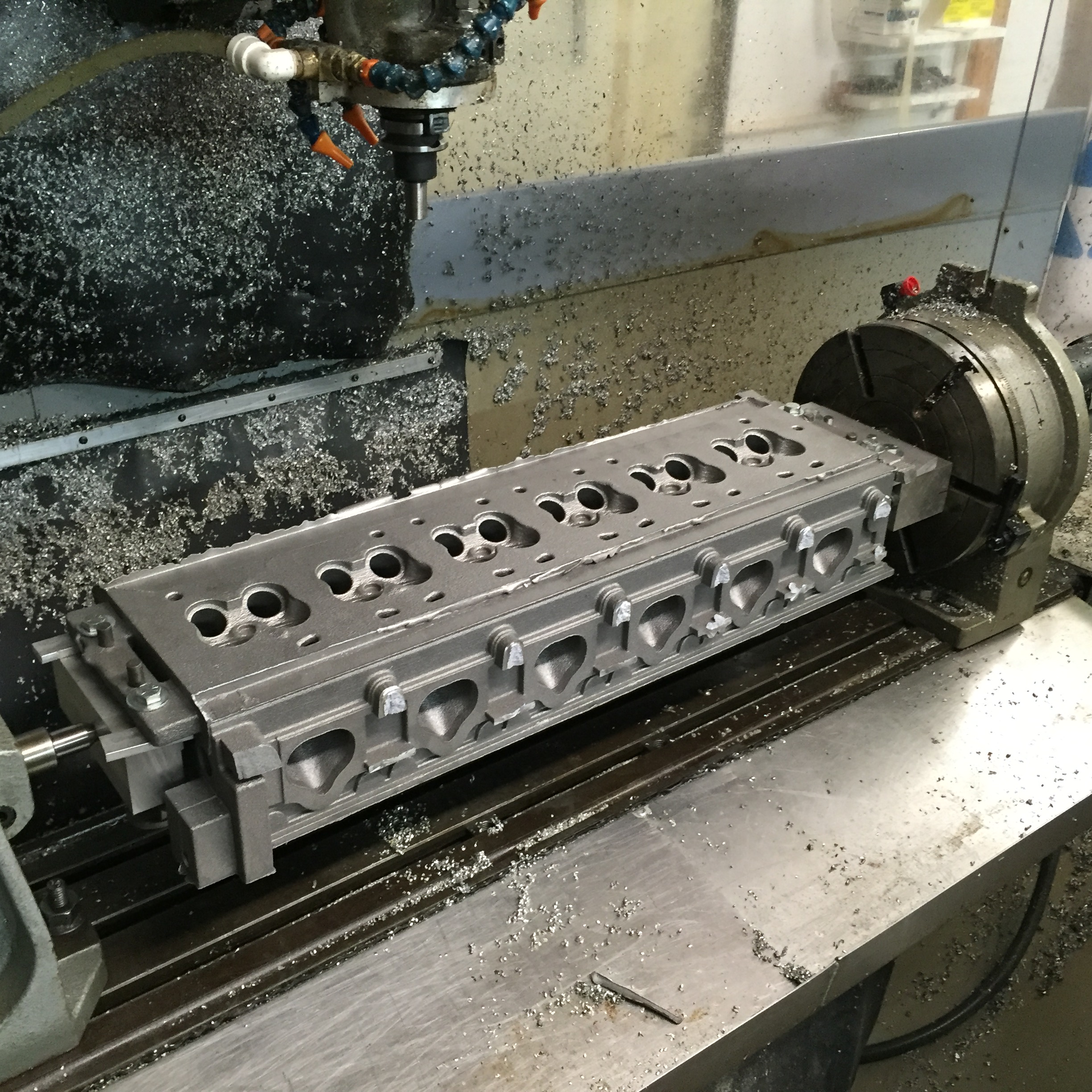

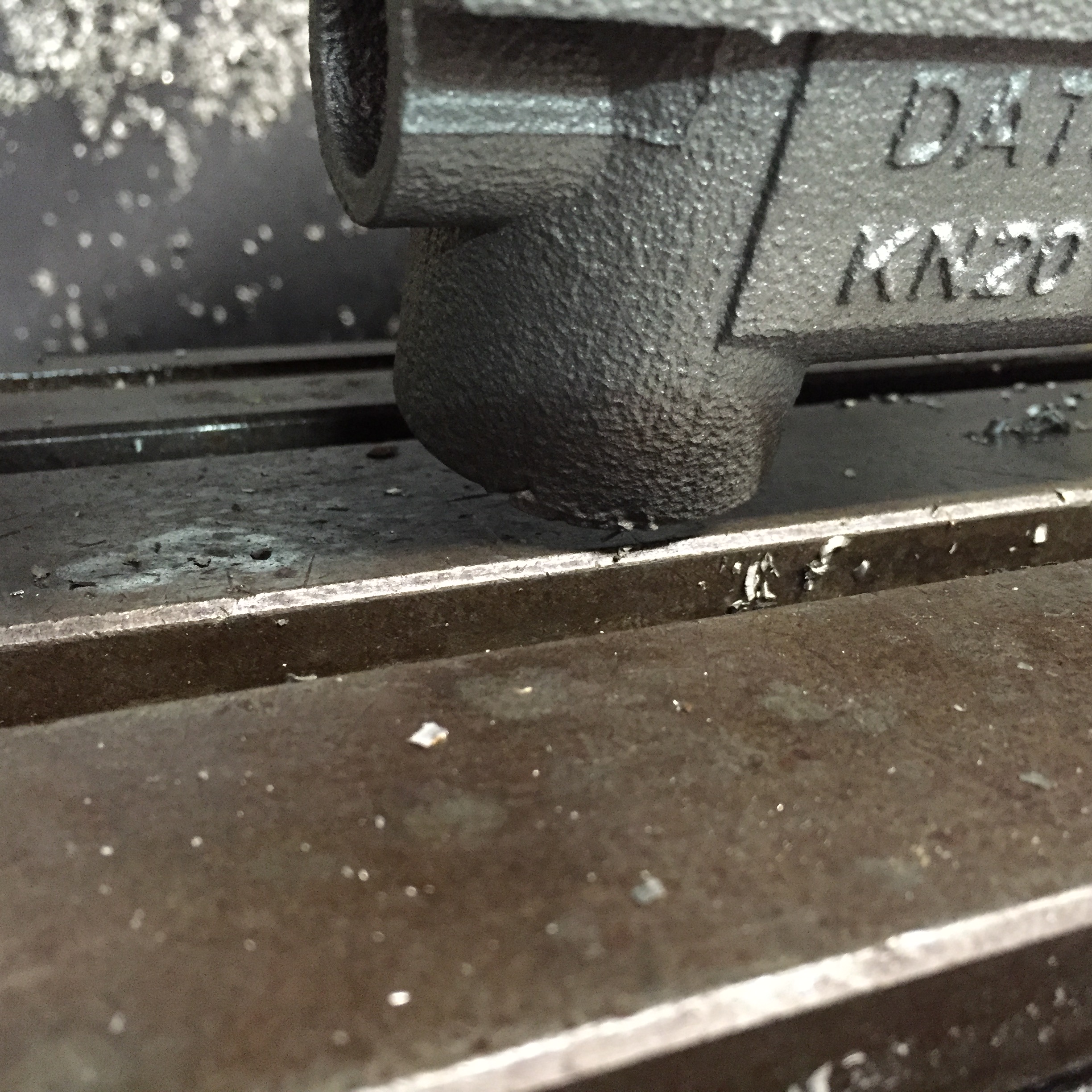

The head has been held up waiting on radiology testing so I’ve been working on other components.

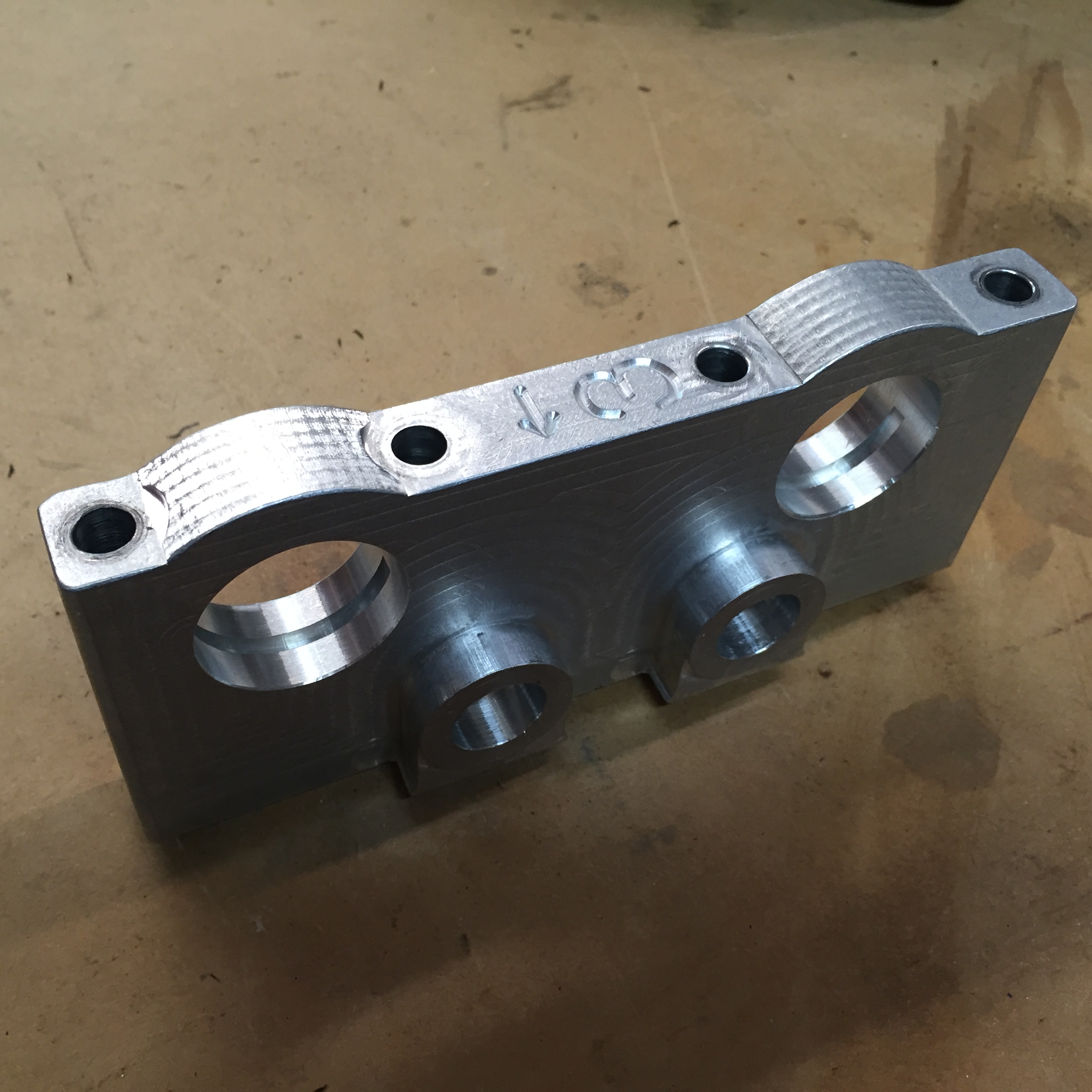

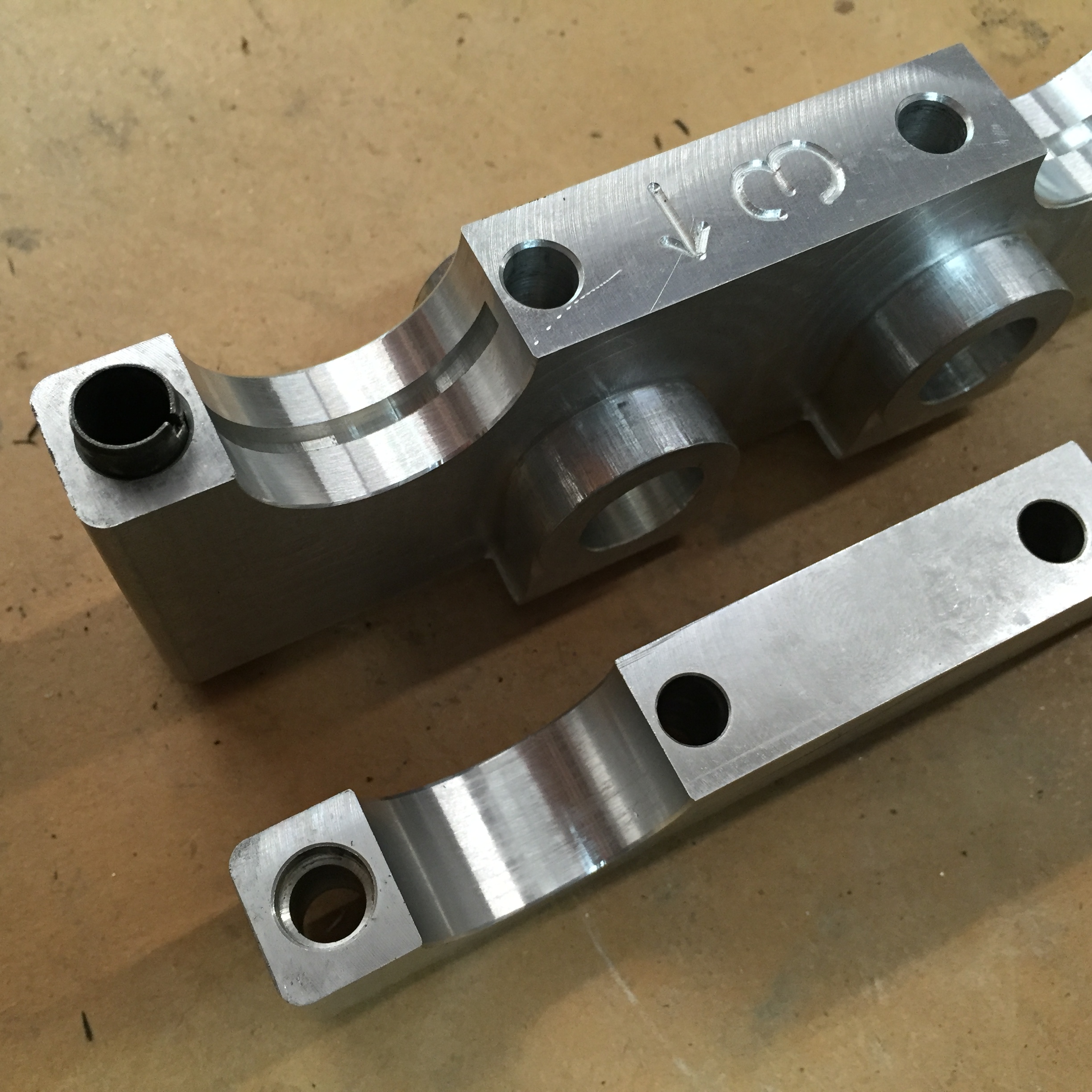

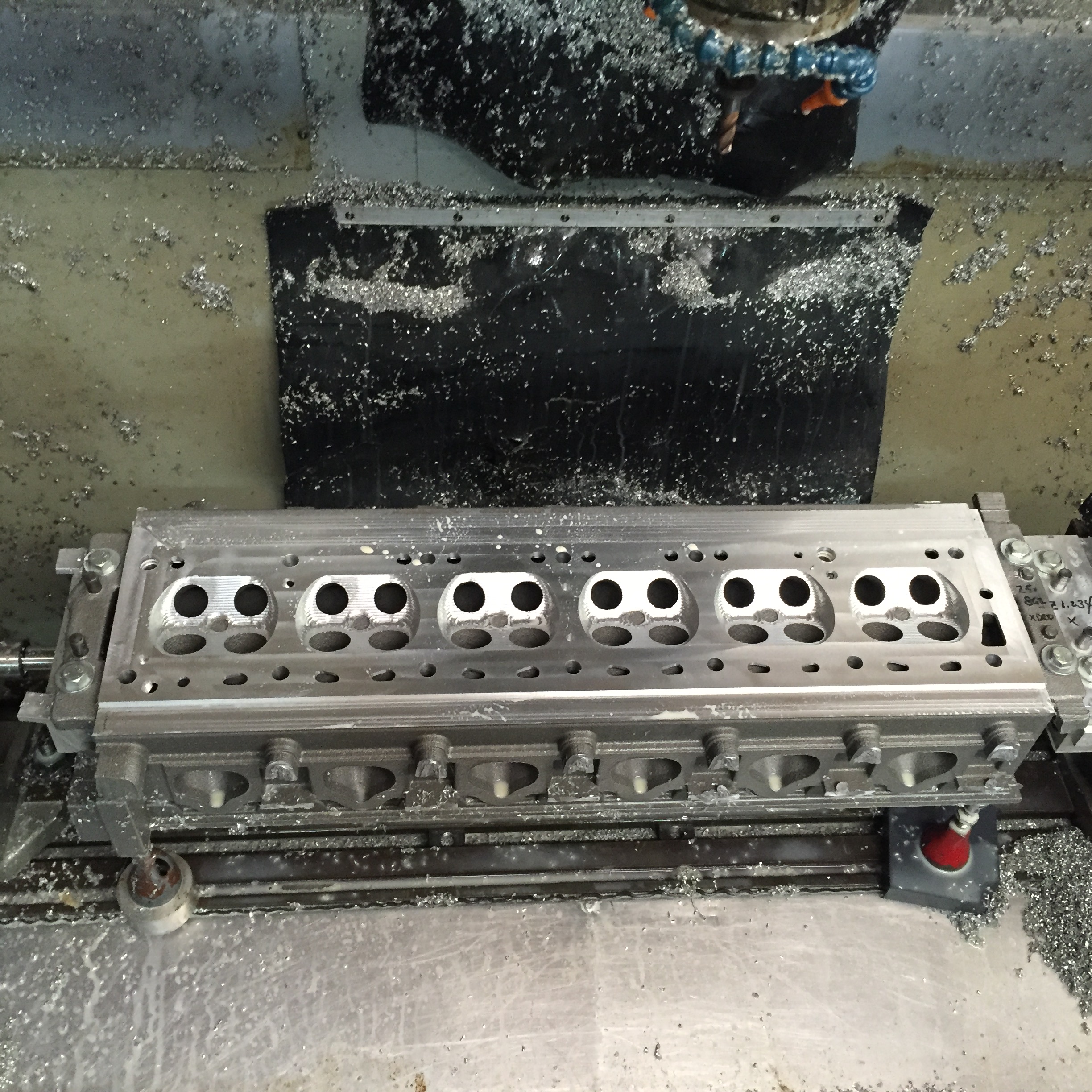

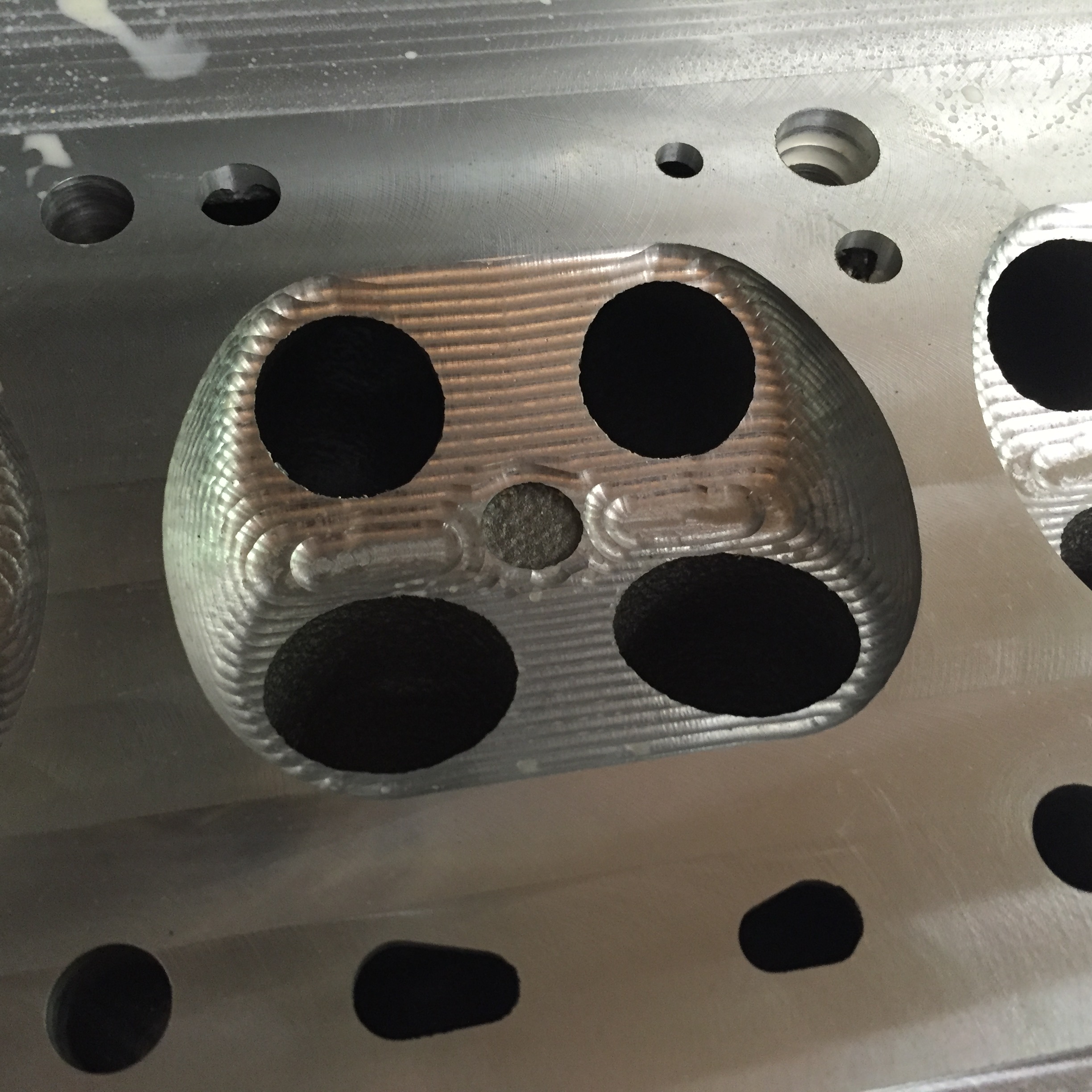

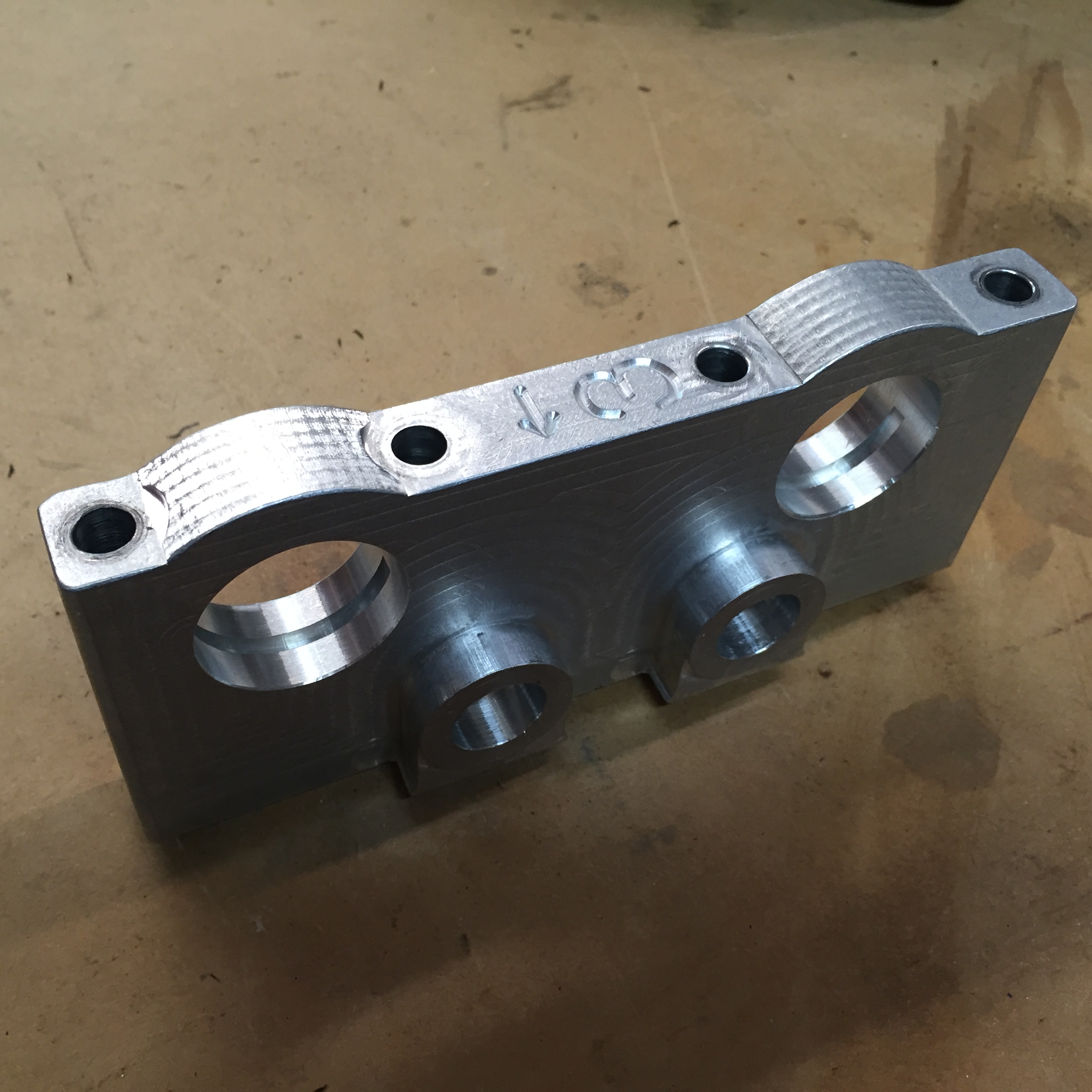

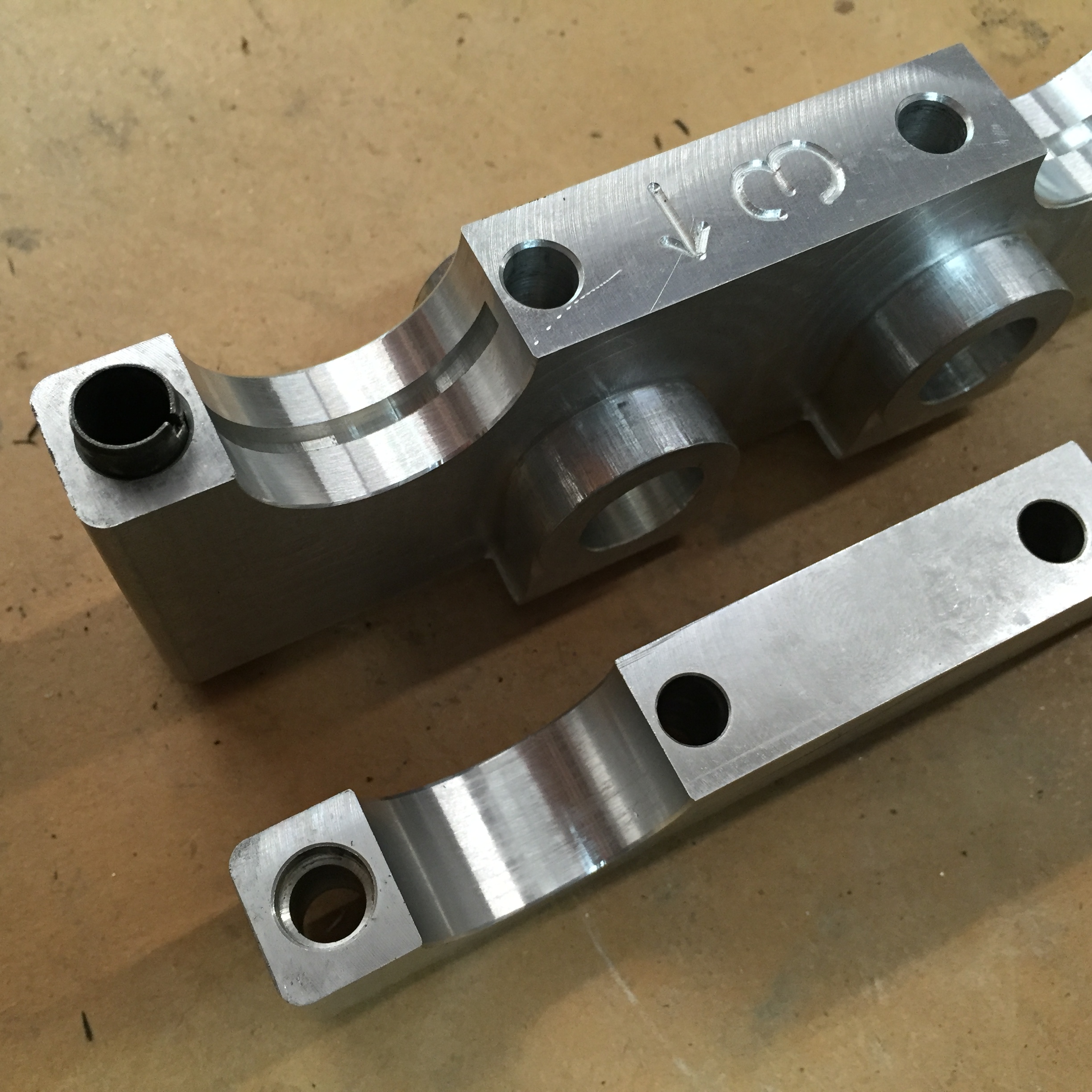

So I bit the bullet and decided to try my hand at making cam towers. They are machined out of 6061 T6 and match the factory specs except for the cam bore size. I opened the bore up to 1.25″ since I have a nice Sunnen hone and the smallest it will go is 1.25″. I increased the cap thickness accordingly.

I also changed the design on the cams a bit. The front is the same as a KA24 and matches the cam gear. I’m doing away with the adjustable hubs and replacing them with multiple dowel holes and a drilled gear. With this combo I’ll be able to have 1.25 degrees of adjustment with 2 dowel pins. Stronger, cheaper, better.

I’m also incorporating the thrust bearings into the cams and having Crane grind them to size when they do journal #1. The main reason for this was it let me increase the diameter of the camshaft at the end. Mucho stronger.

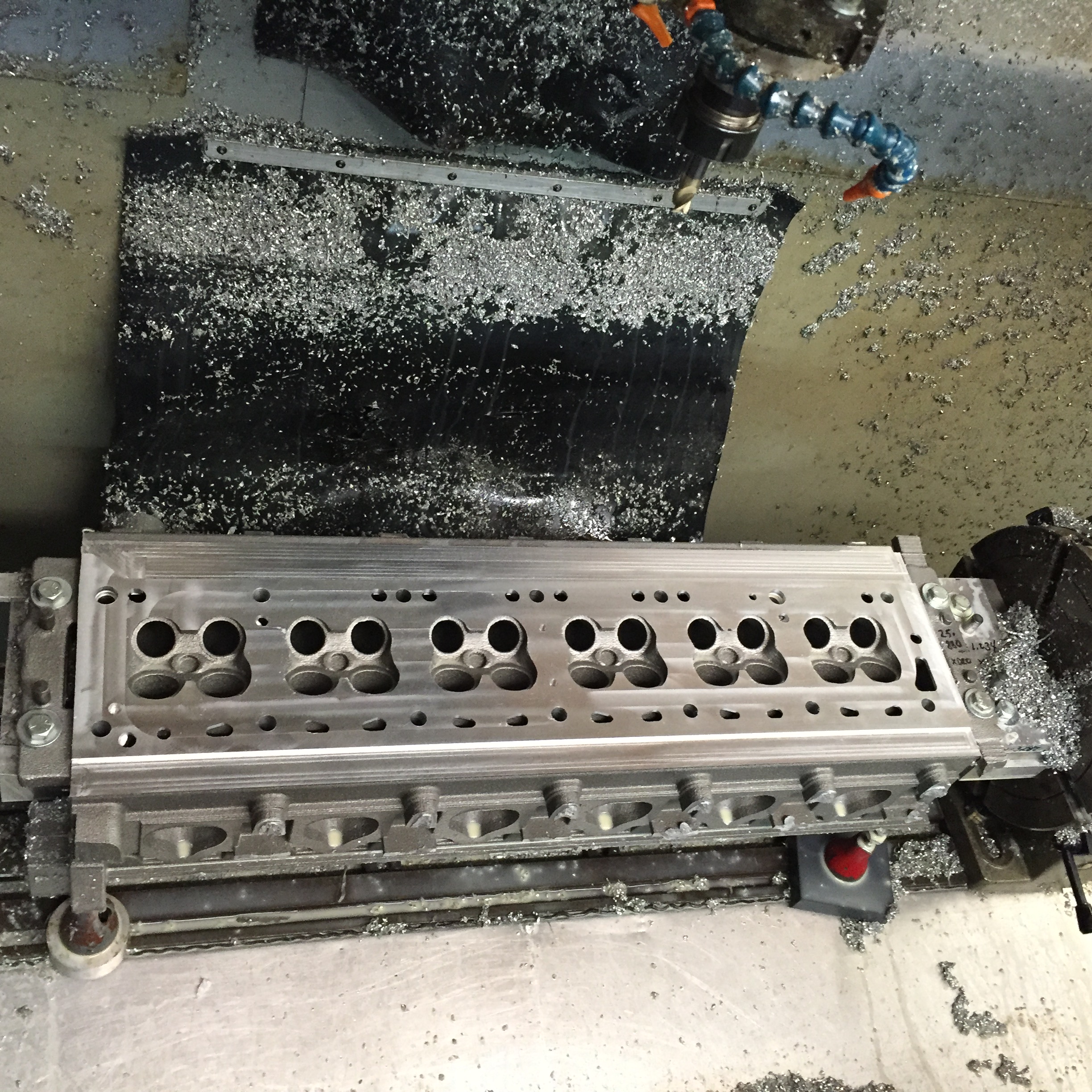

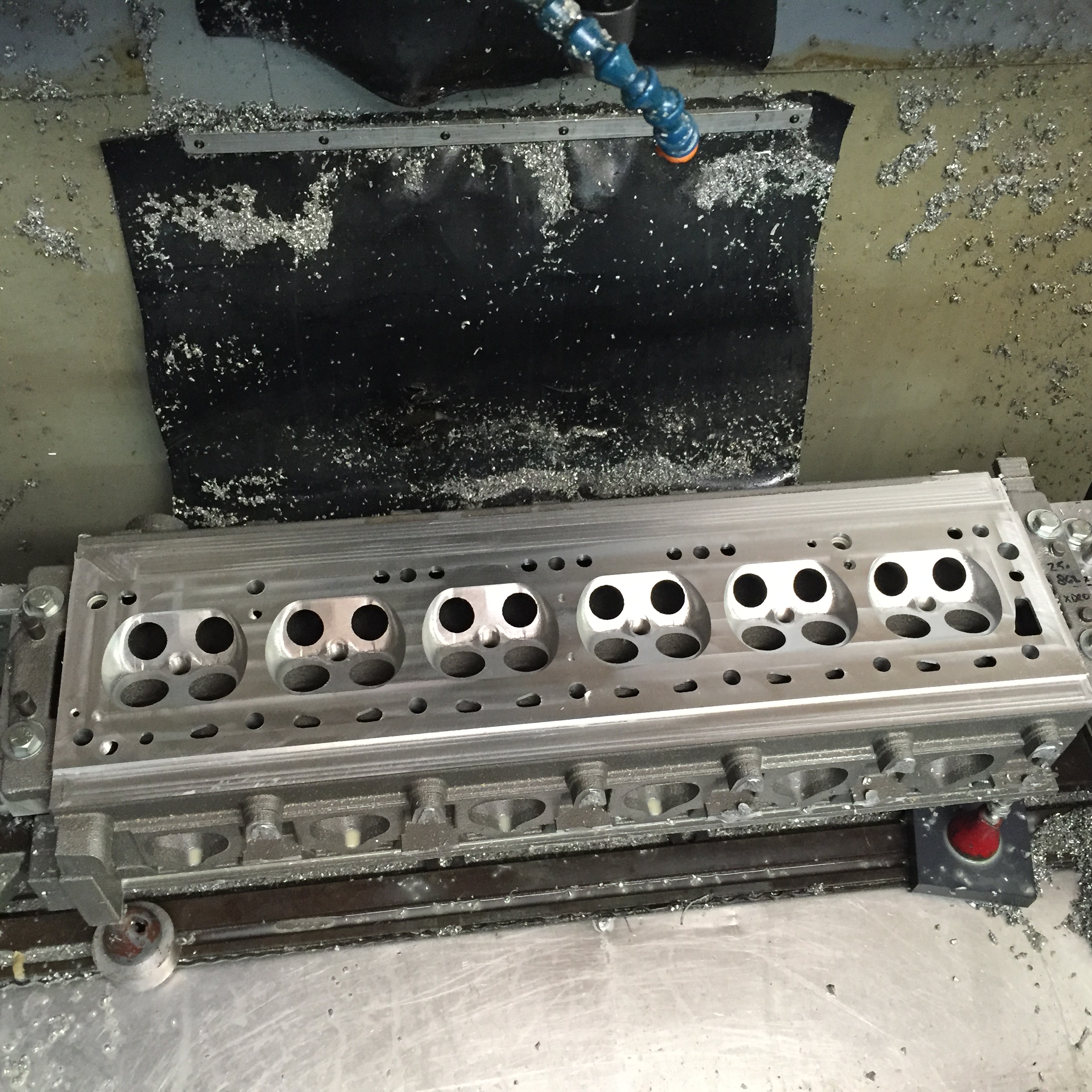

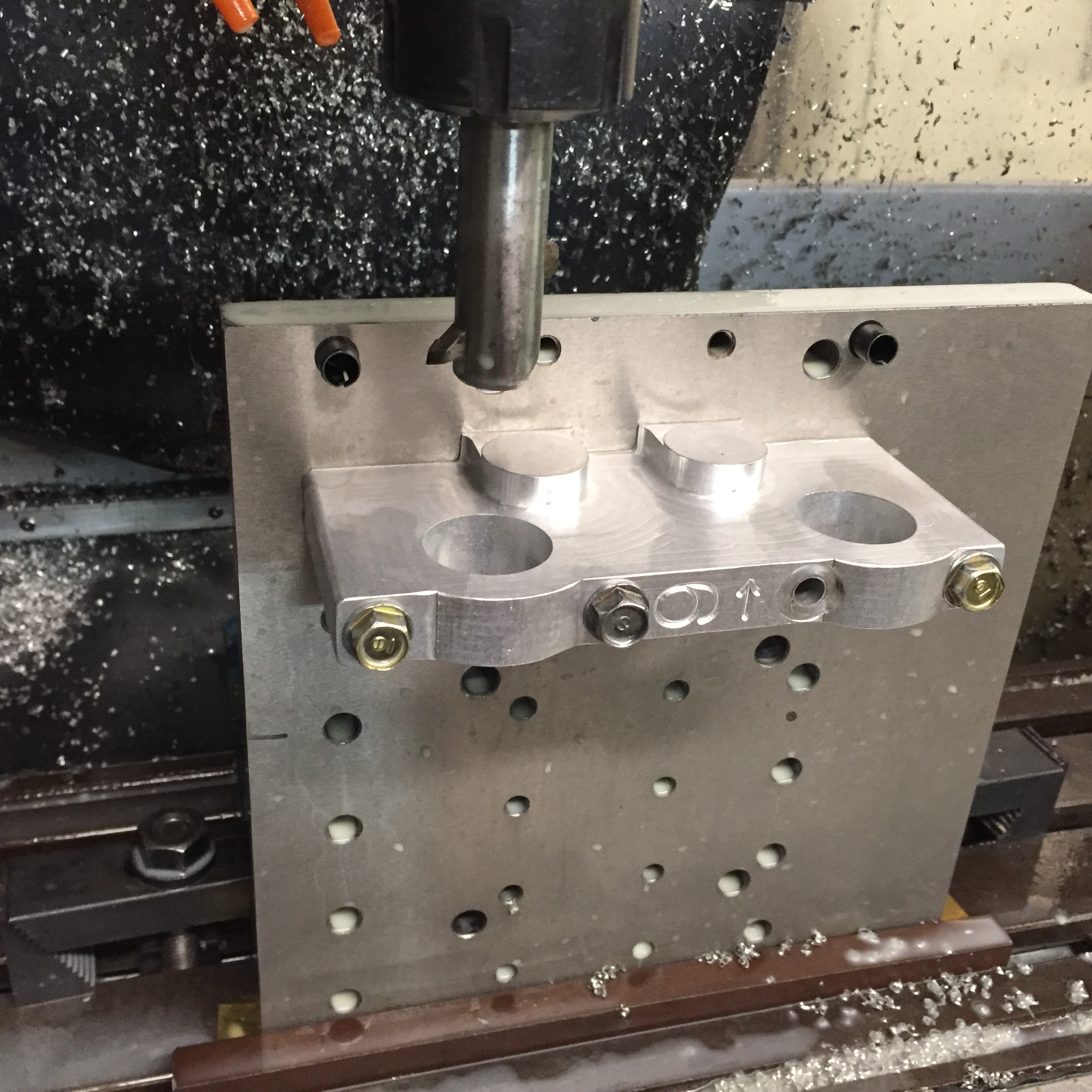

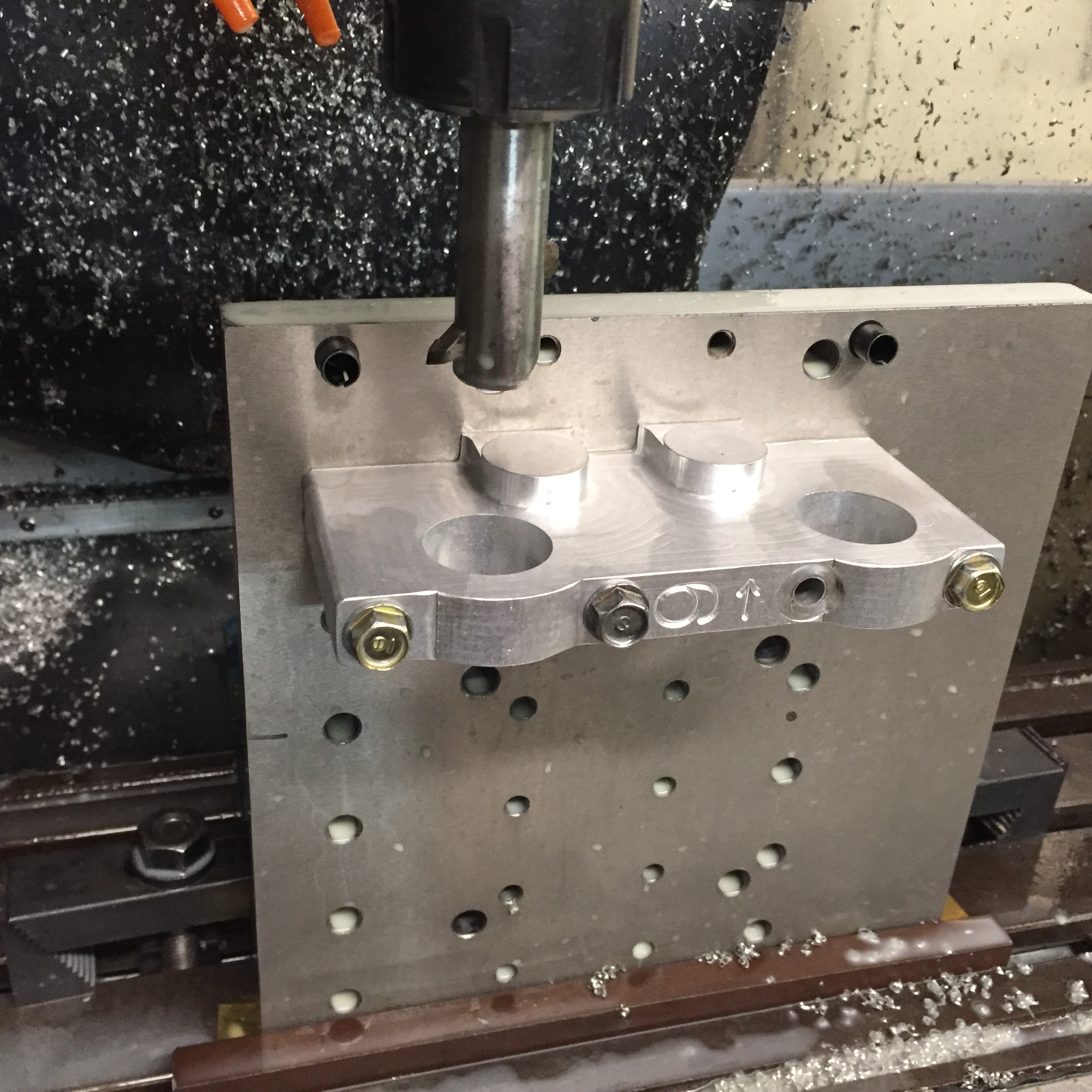

I made a fixture plate to bore all 7 towers at a time but for right now I’m only doing one at a time. I bore each opening without moving the table switching the towers in and out. This way the bores are all in line. Went a lot faster than I thought it would.

The bores came out wicked smooth. Much better than the used towers I’m running on mine.