Sorry I haven’t posted any new content lately. I’ve been super busy.

I did manage to get this done though.

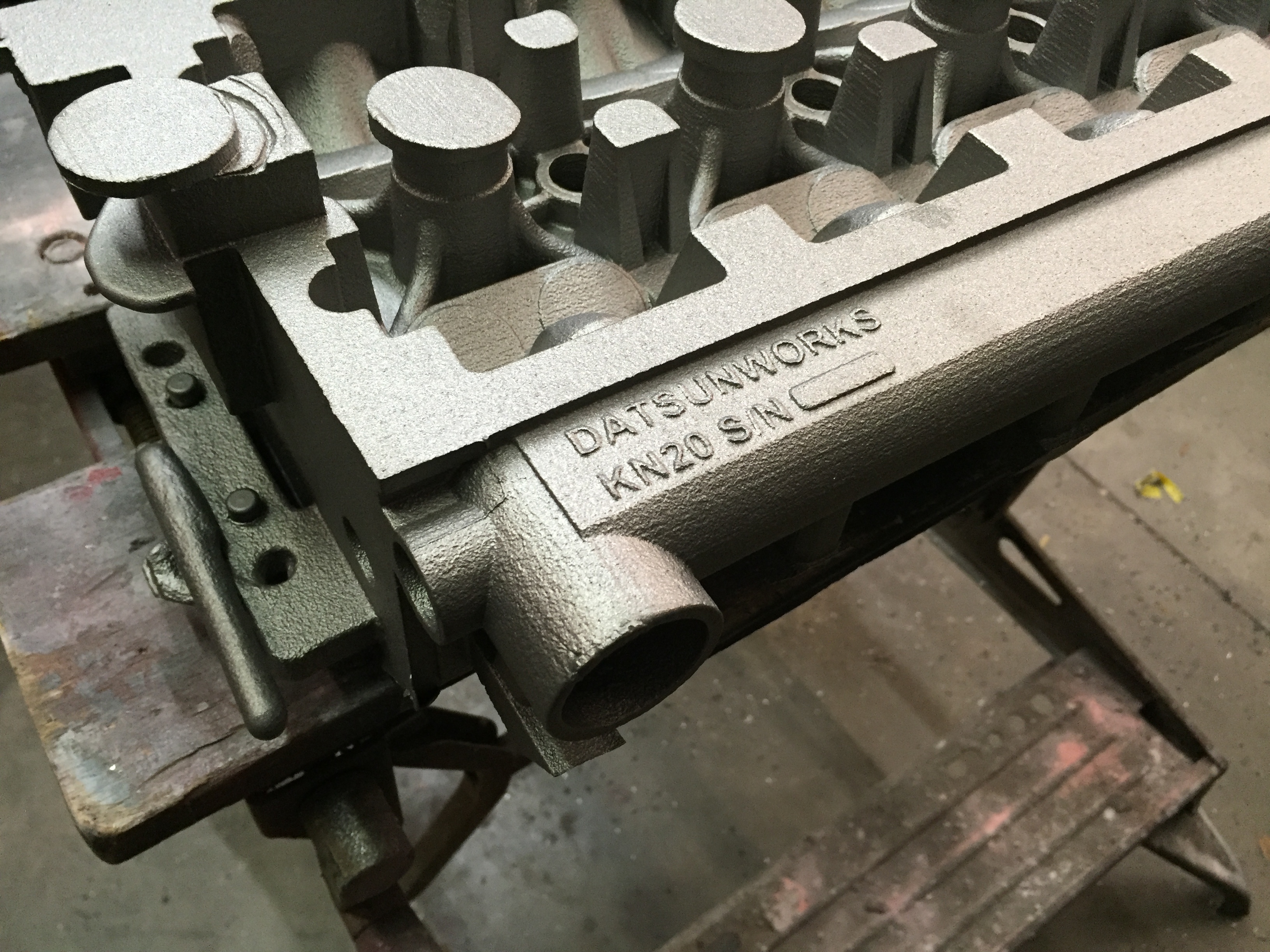

This is V2 of the head and most likely the production version. The major changes are:

I now have the water exiting over each exhaust port and flowing into a central tube. This is the same way OSG and others do it. I opted to try and make it part of the casting to save the cost of making a separate water manifold. Plus it’s a really good example of how versatile 3D sand printing is. The outlet is designed to be tapped 1 1/4″ NPT but you could easily weld something on instead.

I added a rear sump for the oil to drain into the stock oil return. This will do away with the external drain tube that I’m currently using.

I bridged the rear cam tower boss and added a connecter between the back of the head and the tower. This is where the rear oil feed will go.

I redesigned the combustion area so that it has plenty of meat for those who want to get creative.

There are a ton of little changes that reflect things I ran into during the machining of the prototype.

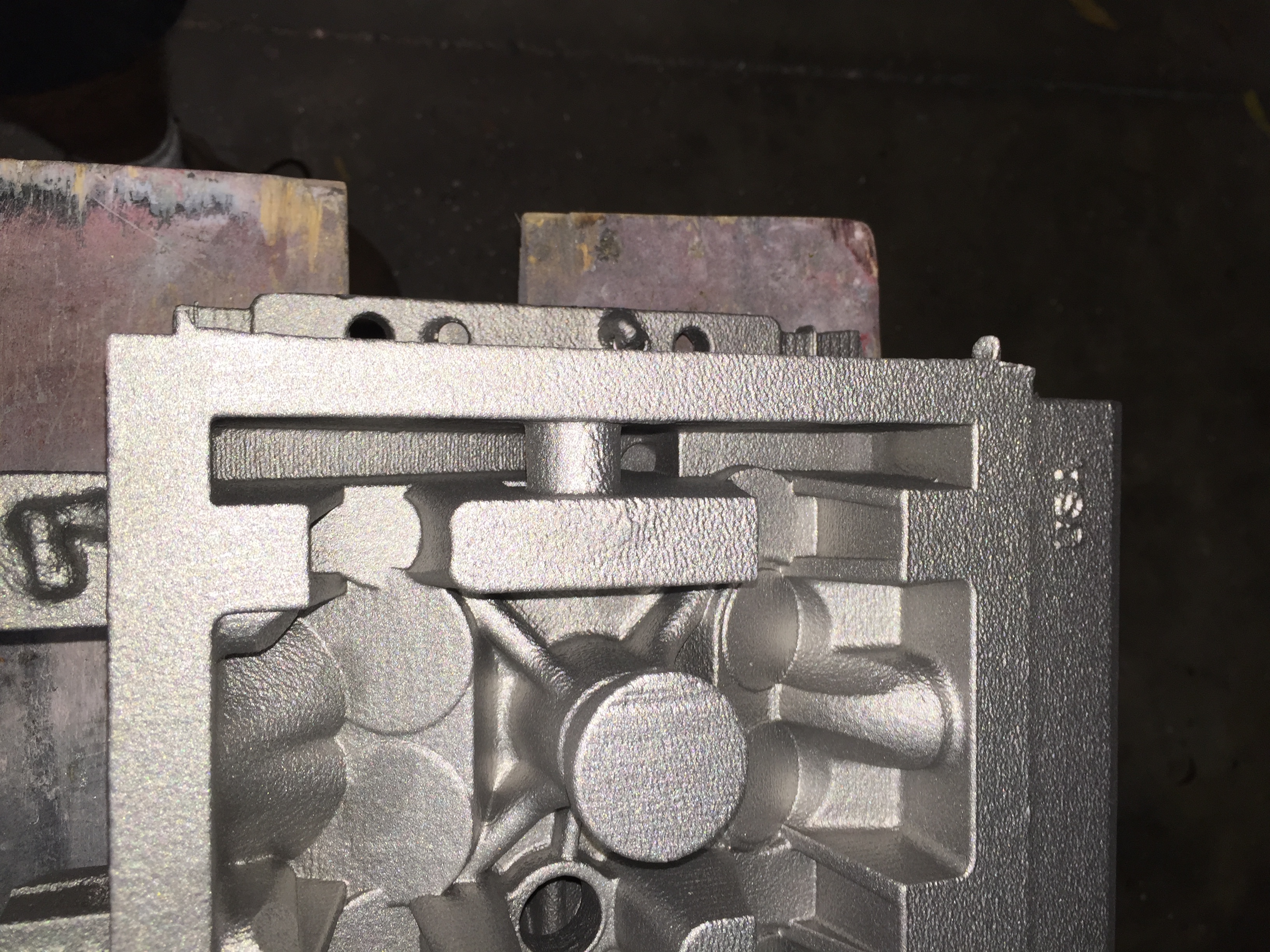

Here is a great shot that shows 3 of the upgrades. The sump, the feeder boss and one of the water exit ports.

Here is the combustion area. The sand is really rough because I went a little overboard blowing out the loose sand. It all get’s machined anyway.

Water outlet and core print in the front of the tube. The core prints are designed to be tapped 3/4″ NPT so that one could be uses for a sensor.

Now I just need to find time for the machine work

Thanks

Derek