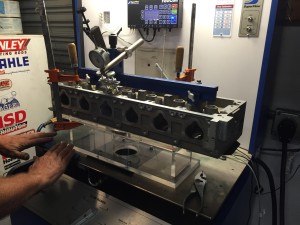

So I took the head down to Scott’s Racing engines to get it Flow tested.

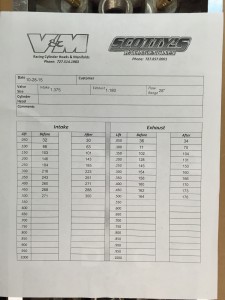

The before column is a raw port with only the machine work for the port matching done. The after has been cleaned up really quickly with a double cut round burr and then I hit it with a cartridge roll on a mandrel. All I did was remove the sand casting texture, blend the steps between the seats and ports, and remove the additional material from the halve guide bosses.

The clear acrylic manifold Had a 3.5″ bore.

They applied modeling clay to the intake ports to smooth the air entry and they held a tube against the exhaust port to simulate a header.

Here is the before port. You can see the steps between the valve seats and the ports are still there and the valve stem bosses are too long.

Here is my piss poor after port. You can see there is plenty of room for improvement with my porting abilities:)

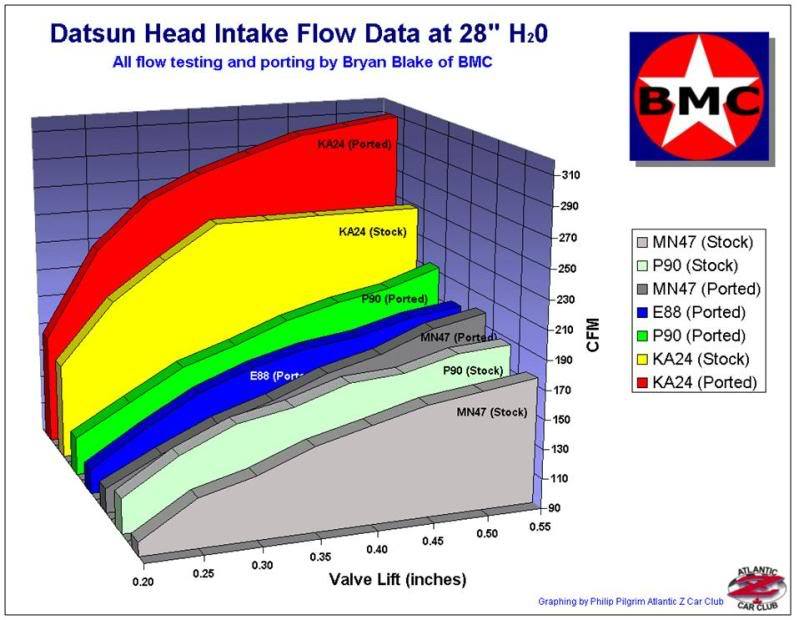

This is a flow comparison chart don by Bryan Blake of BMC. If I trust anyones numbers it would be his. As you can see my head is well above the stock KA and really close to Bryan’s ported KA.

They are just initial numbers but they do follow what I hoped to see based on my port volumes. When I was designing it I looked up the kind of volumes the K20 head gurus were running and I tried to hit those marks. Especially on the intake. The exhaust is fairly close to the stock K20 in shape but the intake is mine from scratch. I started with the stock entry and exits and made it look pretty in between.