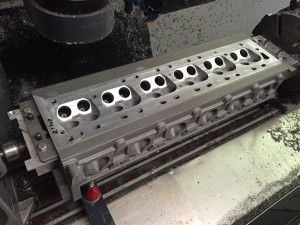

Made some progress today. Got the chambers mapped out and ran a finish pass over them. I designed the chambers to be “as cast’ but I knew that was a mistake as soon as I saw the casting. Since I didn’t have any machine allowance to work with I did the best I could. There are a few spots I’ll have to hand work. I finished the surfacing and recut the water passages to make sure they were in the right spot. They were off a hair. Really happy with the quality of the casting so far. I engineered the gating system to prioritize the combustion chambers and bottom of the head. The metal is super clean so far.

I’m going to need a lot of piston clearance for this to work ![]()

Deep drilling the head bolt holes. This stuff make my butt hole clench.

Bottom all done. (I think)

This is the ground flat bar that I’ll use to set the rotational angle when I roll it over. That way I’m indicating off of the bottom surface.